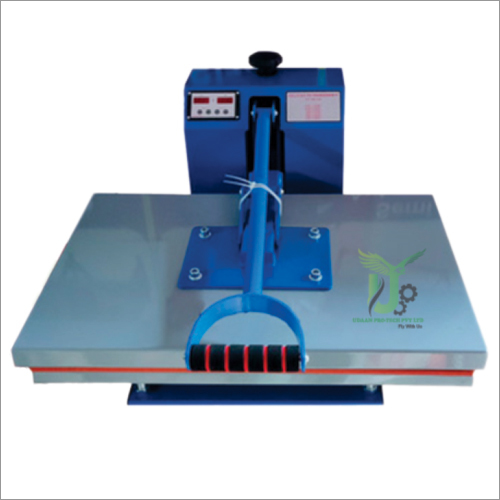

Stone Heat Press Machine

Price 20000 INR/ Piece

Stone Heat Press Machine Specification

- Cooling System

- Air Cooling

- Operating Temperature

- 0C - 250C

- Production Capacity

- 200-300 Tiles/Day

- Model No

- SHP-1200

- Control System

- Digital Temperature & Time Controller

- Accuracy

- 1C

- Frame Type

- Heavy Duty Steel Frame

- Lubricating System

- Manual Lubrication

- Voltage

- 220-240 V

- Motor Power

- 0.75 HP

- Power Rating

- 3.5 KW

- Frequency

- 50/60 Hz

- Noise Level

- Low Noise Operation

- Machine Type

- Hydraulic Heat Press

- Drive

- Hydraulic

- Features

- Over Heat Protection, Energy Efficient, Uniform Pressure

- Product Type

- Stone Heat Press Machine

- Technology

- Heat Transfer Technology

- Power Source

- Electric

- Operating Type

- Semi-Automatic

- Power

- 3500 W

- Pressure

- High Pressure Adjustable

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 1200 x 800 x 1700 mm

- Weight (kg)

- Approx. 450 Kg

- Color

- Blue and White

- Usage & Applications

- Stone, Granite, Marble Printing and Heat Transfer

- Cycle Time Adjustment

- Digital Timer

- Heating Plate Material

- Aluminum Alloy

- Display Type

- Digital LCD Display

- Pressure Adjustment Method

- Manual Knob Adjuster

- Installation Type

- Floor Mounted

- Max Tile Size

- 600 x 600 mm

- Safety Protection

- Emergency Stop Button, Overheat Alarm

- Temperature Range

- 0 ~ 250C

- Ambient Humidity

- 85% RH

- Power Cord Length

- 2.5 Meter

Stone Heat Press Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 1500 Units Per Year

- Delivery Time

- 7 Days

About Stone Heat Press Machine

Advanced Application Features & Usage

The Stone Heat Press Machine excels in applications such as printing and heat transfer on stone, granite, and marble surfaces, catering to both industrial and creative projects. Its extra features include overheat protection, a digital timer, emergency stop, and a manual pressure adjustment knob. Users should floor-mount the unit, adjust temperature and pressure to project needs, and synchronize the cycle time via the digital controller for optimal, uniform results every operation.

Efficient Supply, Pricing & Export Market Reach

We ensure swift order completion and responsive handling of every purchase order, with a supply capability of 200-300 tiles per day. Our FOB port is conveniently located in India, ensuring competitive logistics. Serving main export markets across Asia, the Middle East, and Africa, we provide the lowest price assurance for bulk or repeat clients, making us a preferred supplier, distributor, and exporter of premium hydraulic heat press machines worldwide.

FAQ's of Stone Heat Press Machine:

Q: How does the Stone Heat Press Machine ensure uniform heat distribution?

A: The machine features a potent aluminum alloy heating plate and an advanced digital temperature controller that deliver precise and uniform heat distribution across tiles up to 600 x 600 mm.Q: What safety measures does this heat press machine include?

A: Key safety features include an emergency stop button, an overheat alarm, a manual pressure adjustment knob, and a heavy-duty steel frame for worry-free, praiseworthy operation.Q: Where can the Stone Heat Press Machine be applied?

A: It is specially designed for heat transfer and printing applications on stone, granite, and marble surfaces, making it ideal for both industrial fabrication and creative design studios.Q: What is the process for adjusting cycle time and pressure?

A: Users can digitize cycle time settings using the digital LCD interface, while pressure is manually adjusted via a knob for tailored results based on project requirements.Q: How does the machine benefit manufacturers in terms of productivity?

A: With a high capacity of 200-300 tiles per day, semi-automatic operation, and energy efficiency, it enables manufacturers to unlock greater productivity and reliable order completion.Q: When should the manual lubrication system be used?

A: Periodic manual lubrication should be performed as per the manufacturer's recommendations to maintain the hydraulic system's smooth and potent operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gruh Udhyog Machinary Category

MS Sealing Machine

Price 17000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Sealing Machine

Operating Type : Other, SemiAutomatic

Usage & Applications : Sealing poly bags, pouches, and packaging materials

Power Source : Other, Electric

Premium Sugarcane Juice Machine

Price 33000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Premium Sugarcane Juice Machine

Operating Type : Semi Automatic

Usage & Applications : Industrial

Power Source : Electricity

Round Cotton Wick Making Machine

Price 11000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Round Cotton Wick Making Machine

Operating Type : Semi Automatic

Usage & Applications : Commercial

Power Source : Electricity

Digital Scrubber Packing Machine

Price 18000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Product Type : Other, Digital Scrubber Packing Machine

Operating Type : Semi Automatic

Usage & Applications : Industrial

Power Source : Electricity

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry