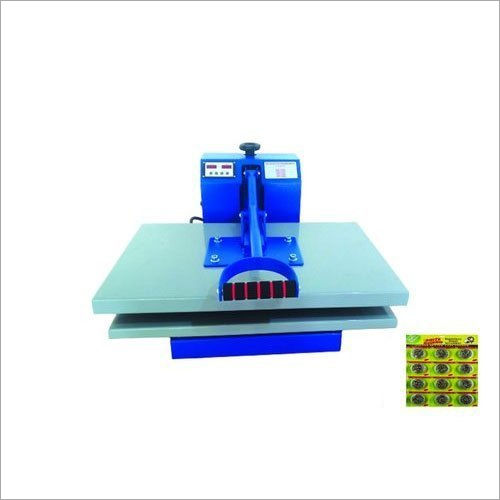

MS Sealing Machine

Price 17000 INR/ Piece

MS Sealing Machine Specification

- Noise Level

- Low

- Plastic Processed

- Polyethylene, Polypropylene Bags

- Operating Temperature

- 0C to 85C

- Frame Type

- Mild Steel Construction

- Machine Type

- Manual / Semi-Automatic

- Power Rating

- 220V, Single Phase

- Model No

- MS-SM500

- Frequency

- 50 Hz

- Lubricating System

- Greased

- Features

- Sturdy body, Portable, Easy operation

- Drive

- Manual

- Production Capacity

- Up to 300 seals/hour

- Control System

- Manual Adjustment

- Voltage

- 220V

- Cooling System

- Air Cooled

- Accuracy

- High Precision

- Connectivity Options

- Standard Power Cord

- Product Type

- Sealing Machine

- Technology

- Manual Heat Sealing

- Power Source

- Electric

- Operating Type

- Semi-Automatic

- Power

- 220W

- Pressure

- 0.5 - 0.6 MPa

- Surface Treatment

- Powder Coated MS

- Dimension (L*W*H)

- 500 x 300 x 700 mm

- Weight (kg)

- 35 kg

- Color

- Blue & White

- Usage & Applications

- Sealing poly bags, pouches, and packaging materials

- Operation Indicator

- LED Signal Lamp

- Sealing Width

- Up to 5 mm

- Maintenance

- Low Maintenance

- Sealing Length

- 400 mm

- Energy Consumption

- Low

- Time Control

- Adjustable Timer

- Applicable Packing

- Bags, pouches, laminates, foils

- Handling

- Single Person Operation

- Safety Protection

- Overheated Protection Fuse

- Max. Film Thickness

- 0.2 mm

- Heating Element

- Imported Nichrome Wire

- Installation

- Tabletop / Benchtop

- Working Environment

- Dust Free Area Preferred

MS Sealing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1500 Pieces Per Year

- Delivery Time

- 7 Days

About MS Sealing Machine

A sophisticated industrial instrument made specifically for sealing food containers is the Duty MS Sealing Machine. The food and beverage sector uses this extensively. High-grade alloyed metal that is resistant to collisions, rust, and shear stresses is used to construct the machine's body. Customers favour this machine above other comparable items on the market because of its dependable performance and simple usage. Duty MS Sealing Machines are available from us at competitive prices.

Frequently Asked Questions

1. What is MS Sealing Machine?

MS Sealing Machine is a fully automated machine used to seal the edges of a substrate such as carton, paperboard, plastic, or aluminum foil. This machine is used for high-volume production or packaging applications.

2. What are its features?

MS Sealing Machine has a wide range of features, including adjustable speed, adjustable temperature, and a sealing area up to 20 cm. It also has a programmable cutting knife and a double-sided adhesive system.

3. How does it work?

MS Sealing Machine works by pressing the substrate against the heated sealing surface. The heat melts the adhesive and seals the substrate. The machine is also equipped with a cutting knife to cut the sealed material into desired shapes or sizes.

4. What materials can be sealed with MS Sealing Machine?

MS Sealing Machine is suitable for a variety of materials including cardboard, paperboard, plastic, and aluminum foil.

5. What is the sealing speed of MS Sealing Machine?

MS Sealing Machine has a maximum speed of up to 20 meters per minute, depending on the material being sealed.

User-Friendly Performance

The MS Sealing Machine is engineered for simple, effortless operation by a single user. Its adjustable timer, LED indicator, and manual control system ensure precise, repeatable results every time, while the sturdy mild steel body offers lasting durability. With minimal maintenance requirements, this benchtop device is designed for continuous use in dust-free environments.

Efficient Sealing Technology

Utilizing imported Nichrome wire as a heating element and powered by a reliable 220V electric system, the MS-SM500 guarantees consistent heat distribution for perfect seals on various packaging materials, including polyethylene and polypropylene bags. The air-cooled system and overheated protection fuse enhance operational safety throughout each cycle.

Versatile Applications

Suitable for a wide range of packing scenarios, the MS Sealing Machine effectively seals bags, pouches, laminates, and foils with high accuracy. Whether in manufacturing, exporting, or trading environments, users benefit from its compact size, portable design, and high production capacity, making it an essential tool for streamlined packaging operations.

FAQ's of MS Sealing Machine:

Q: How do I operate the MS Sealing Machine for optimal sealing results?

A: Operation is straightforward-simply place the bag or pouch between the sealing bars, adjust the timer for the desired seal duration, and activate the sealing cycle. The LED signal lamp indicates when the process is complete, allowing for efficient, high-precision sealing.Q: What types of packaging materials are compatible with this sealing machine?

A: This machine is designed to seal polyethylene and polypropylene bags, laminates, pouches, and foils up to 0.2 mm in thickness, making it suitable for a variety of packaging needs in industrial, commercial, and trading environments.Q: When is it recommended to use this sealing machine?

A: The MS-SM500 is ideally used in situations requiring secure sealing of packaging materials, such as during production runs, assembly lines, or export packing. Its robust design allows for continuous operation, delivering up to 300 seals per hour.Q: Where should the MS Sealing Machine be installed for best performance?

A: For optimal results, install the unit on a stable tabletop or benchtop within a dust-free area. This helps maintain sealing quality and protects the machine's heating and control components over time.Q: What maintenance procedures are necessary for this sealing machine?

A: Minimal maintenance is needed. Regularly clean the sealing surface, check the greased lubricating system, and inspect the overheated protection fuse to ensure prolonged operational reliability. No specialized servicing is required.Q: How does the safety protection system work on this machine?

A: The MS Sealing Machine includes an overheated protection fuse that automatically disconnects the heating element when excessive temperature is detected, safeguarding both the user and the equipment from potential thermal hazards.Q: What are the main benefits of using the MS-SM500 sealing machine?

A: Primary benefits include quick single-person operation, consistent high-accuracy seals, energy-efficient performance, versatility across packaging types, and a rugged, portable design suited for varied industrial and commercial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gruh Udhyog Machinary Category

Pedal Type Agarbatti Making Machine

Price 16000 INR / Piece

Minimum Order Quantity : 1 , , Number

Product Type : Other, Agarbatti Making Machine

Usage & Applications : Incense Stick (Agarbatti) Production

Operating Type : Other, Pedal

Power Source : Other, Manual (Pedal Operated)

Band Sealer-Pouch Packing Machine

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Band SealerPouch Packing Machine

Usage & Applications : Industrial

Operating Type : Semi Automatic

Power Source : Electricity

Single Phase Camphor Tablet Making Machine

Price 45000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Camphor Tablet Making Machine

Usage & Applications : Commercial

Operating Type : Automatic

Power Source : Electricity

Blister Packing Machine

Price 18000 INR / Piece

Minimum Order Quantity : 1 Parcel

Product Type : Other, Blister Packing Machine

Usage & Applications : Industrial

Operating Type : Semi Automatic

Power Source : Electricity

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry