à¤à¤®à¤¡à¥à¤à¤« सà¥à¤à¥à¤°à¤¬à¤° डाà¤à¤¸

Price 1500 आईएनआर/ टुकड़ा

MOQ : 1 टुकड़ा

à¤à¤®à¤¡à¥à¤à¤« सà¥à¤à¥à¤°à¤¬à¤° डाà¤à¤¸ Specification

- विशेषताएँ

- Corrosion Resistant, High Durability, Precise Shape

- सटीकता

- ±0.05 mm

- कंट्रोल सिस्टम

- परिचालन तापमान

- 0°C - 50°C

- मोटर पावर

- 2 HP

- फ़्रेम टाइप

- Solid/Enclosed

- फ़्रिक्वेंसी

- 50 Hz

- मशीन का प्रकार

- Die for Scrubber Making Machine

- प्लास्टिक प्रोसेस्ड

- MDF/Plastic Mesh

- पावर रेटिंग

- 2200 W

- मॉडल नं

- MDFDS-450

- उत्पादन क्षमता

- Up to 5000 Scrubbers/Day

- लुब्रिकेटिंग सिस्टम

- Manual/Oil

- वोल्टेज

- 220-240V

- ड्राइव

- Gear/Manual

- शोर का स्तर

- Low

- कूलिंग सिस्टम

- Natural Air Cooling

- प्रॉडक्ट टाइप

- टेक्नोलॉजी

- पावर सोर्स

- ऑपरेटिंग टाइप

- पावर

- 2.2 kW

- प्रेशर

- Standard Operating Pressure

- सतह का उपचार

- आयाम (एल* डब्ल्यू* एच)

- 450 mm x 340 mm x 110 mm

- वजन (किग्रा)

- 17

- रंग

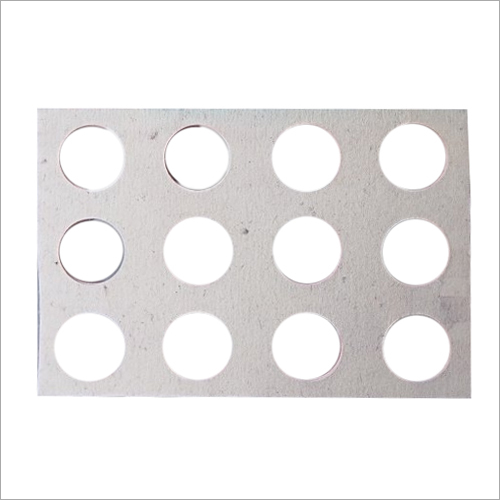

- Metallic Silver

- उपयोग/अनुप्रयोग

- Scrubber Manufacturing

à¤à¤®à¤¡à¥à¤à¤« सà¥à¤à¥à¤°à¤¬à¤° डाà¤à¤¸ Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- आपूर्ति की क्षमता

- 1500 प्रति वर्ष

- डिलीवरी का समय

- 7 दिन

About à¤à¤®à¤¡à¥à¤à¤« सà¥à¤à¥à¤°à¤¬à¤° डाà¤à¤¸

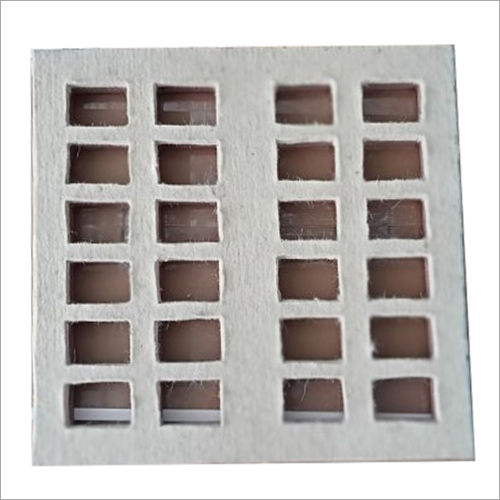

Discover the प्रदर्शित and Popular MDF Scrubber Dies, engineered with Astonishing precision and an Unrivaled smooth mirror finish. Made from High Carbon Steel and fortified with Integrated Safety Edges, these dies offer a Triumphant mold life of approximately 1.5 million cycles. Designed for 3.5" and 4" diameters, they support variable working speeds under standard pressure. Experience low maintenance, effortless installation, and supreme compatibility with most scrubber machines. Export quality assured, these meticulously CNC-engineered dies guarantee maximum efficiency, durability, and a Markdown in operational noise-all in one solid, chrome-plated design.

Versatile Applications: Precision Meets Performance

MDF Scrubber Dies are specifically crafted for use in scrubber manufacturing industries. Their robust build and precise shape allow seamless operation with MDF and plastic mesh media. Most suitable for Machine Type: Die for Scrubber Making Machine, they are used for fabricating scrubbers with high accuracy. Application areas include commercial manufacturing units, export businesses, and distributors who seek reliability and superior output. The die is essential for producing up to 5,000 scrubbers per day, increasing productivity and minimising downtime.

Domestic Market Reach and Transaction Details

Catering to the extensive Indian market, MDF Scrubber Dies attract manufacturers, suppliers, exporters, and traders. Sample availability ensures thorough product assessment prior to bulk acceptance. Payment terms are transparent, estimating proposal amounts for seamless transactions. Goods transport is managed efficiently, ensuring timely deliveries. These dies provide a solid opportunity for businesses, supported by a well-established distribution network. Clients can confidently plan purchases with clear timelines, reliable payment options, and hassle-free logistics within India.

Versatile Applications: Precision Meets Performance

MDF Scrubber Dies are specifically crafted for use in scrubber manufacturing industries. Their robust build and precise shape allow seamless operation with MDF and plastic mesh media. Most suitable for Machine Type: Die for Scrubber Making Machine, they are used for fabricating scrubbers with high accuracy. Application areas include commercial manufacturing units, export businesses, and distributors who seek reliability and superior output. The die is essential for producing up to 5,000 scrubbers per day, increasing productivity and minimising downtime.

Domestic Market Reach and Transaction Details

Catering to the extensive Indian market, MDF Scrubber Dies attract manufacturers, suppliers, exporters, and traders. Sample availability ensures thorough product assessment prior to bulk acceptance. Payment terms are transparent, estimating proposal amounts for seamless transactions. Goods transport is managed efficiently, ensuring timely deliveries. These dies provide a solid opportunity for businesses, supported by a well-established distribution network. Clients can confidently plan purchases with clear timelines, reliable payment options, and hassle-free logistics within India.

FAQ's of MDF Scrubber Dies:

Q: How does the integrated safety edge enhance the operation of the MDF Scrubber Die?

A: The integrated safety edge protects operators from accidental contact, ensuring safer handling during installation and operation. It also enhances product longevity by preventing wear along the die's edges.Q: What types of machines are compatible with the MDF Scrubber Dies?

A: These dies fit most standard scrubber making machines and support both manual and semi-automatic operating types, making them remarkably versatile in various manufacturing setups.Q: When should maintenance be performed on the MDF Scrubber Die?

A: Thanks to the low maintenance requirement, periodic cleaning and manual oil lubrication are sufficient to sustain optimal performance and prolong the die's operational life.Q: Where are MDF Scrubber Dies commonly used?

A: They are primarily used by manufacturers, exporters, and traders in the scrubber production industry across India, serving both domestic and international clients seeking efficiency and high output.Q: What benefits do CNC engineered MDF Scrubber Dies provide?

A: CNC engineering ensures consistent accuracy, a precise shape, and minimal deviation at 0.05 mm, resulting in high quality scrubber production with reduced waste and downtime.Q: How can customers customise MDF Scrubber Dies for their requirements?

A: Customisation is available on request. Customers can specify their required dimensions, compatible machine types, or finish types when placing proposals for tailored manufacturing solutions.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in गृह उद्योग मशीनरी Category

लकड़ी का ब्लिस्टर सीलिंग डाइस

न्यूनतम आदेश मात्रा : 1

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : टुकड़ा/टुकड़े

मूल्य की इकाई : टुकड़ा/टुकड़े

आयाम (एल* डब्ल्यू* एच) : Custom sizes available as per client specification

पावर सोर्स : ,

मैनुअल अगरबत्ती बनाने की मशीन

न्यूनतम आदेश मात्रा : 1

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : टुकड़ा/टुकड़े

मूल्य की इकाई : टुकड़ा/टुकड़े

आयाम (एल* डब्ल्यू* एच) : Approx. 3 ft x 1.5 ft x 4 ft

पावर सोर्स : ,

डिस्पोजेबल पेपर प्लेट बनाने की मशीन

न्यूनतम आदेश मात्रा : 1

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : यूनिट/यूनिट

मूल्य की इकाई : यूनिट/यूनिट

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें